The Sail-Gen Lite is a dedicated water generator developed for the long distance sailing. It shares the same operating principal as the DuoGen’s water mode, which is well proven over hundreds of thousands of sea miles.

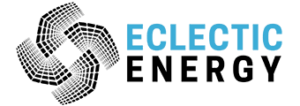

The Sail-Gen Lite comprises a rigid welded aluminium frame with carbon fibre drive shaft and cast alloy impeller. It is compact in size and both reliable and efficient in operation. At typical passage speeds (5 – 6 knots) the Sail-Gen Lite is capable of matching the power consumption on many cruising yachts meaning that the batteries remain well charged.

The Sail-Gen Lite is also extremely easy to deploy and recover and is quiet in operation.

The main features:

● The Sail-Gen Lite is direct-drive, i.e. 1:1 ratio impeller to alternator. There is no gearbox to wear and add friction.

● The Sail-Gen Lite alternator is not submerged, and is therefore less liable to failure through water ingress.

● The Sail-Gen Lite running depth is controlled by a ‘hydro foil’ or ‘dive plane’. This means that the water impeller flies through the wave action at a constant depth and is not directly affected by the pitching movement of the yacht, as occurs with the ‘outboard leg’ type generator.

● The impeller running depth can be optimised by a simple adjustment of the dive plane angle.

● The dive plane prevents the water impeller from surfacing in all but the most extreme situations.

● The Sail-Gen Lite dive plane is active, and moves to a positive angle as tension is applied to the recovery lanyard. This makes recovery simple and easy, regardless of boat speed.

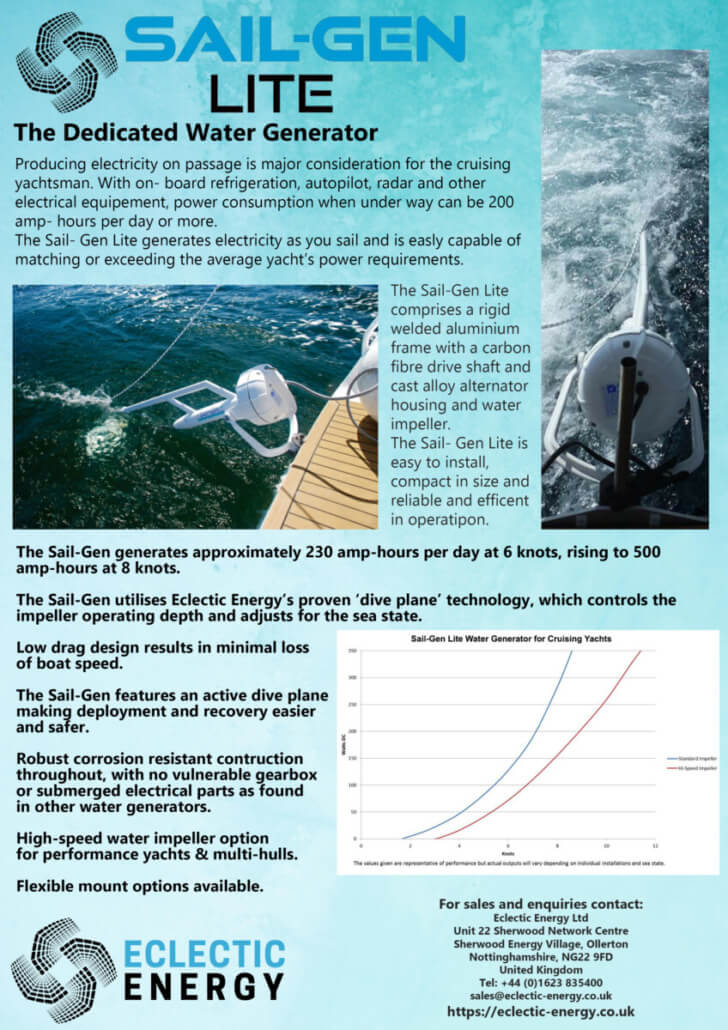

Sail-Gen Lite Power Output Curve

*All performance figures are indicative. Actual outputs may vary. E&OE.