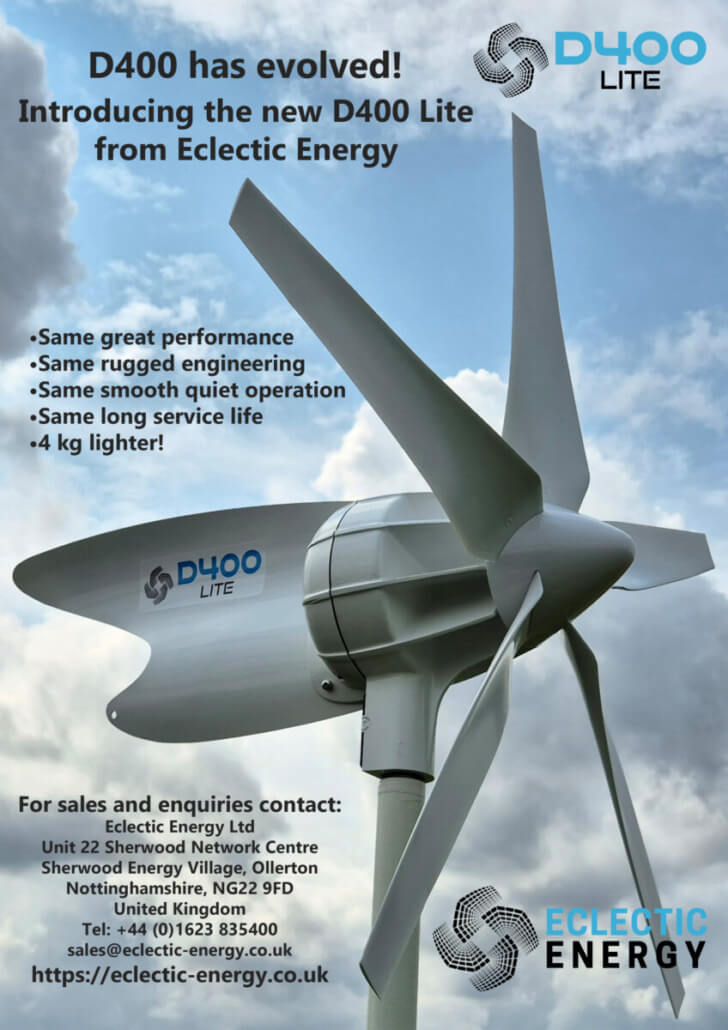

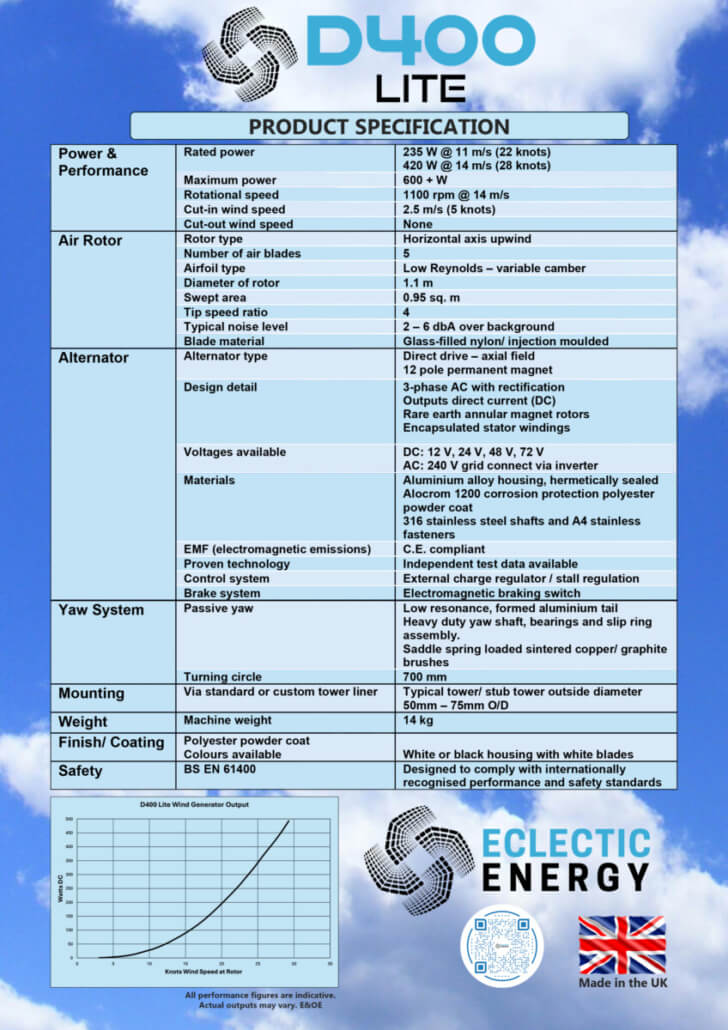

The D400 Lite is extremely efficient by design, making it the most powerful and productive wind generator of its rotor size currently available.

The D400 Lite has been developed specifically to operate in close proximity to people. The noise and vibration usually associated with small wind turbines has been designed out of the D400 Lite. This has been achieved by making the turbine run relatively slowly for a given electrical output. The D400 Lite rotates at less than one quarter the speed of some competitor units. Combined with its rugged engineering and advanced computer-designed air blades, this makes the D400 Lite the most reliable and quietest small wind turbine currently available.

The air blades are precision injection-moulded from glass reinforced nylon and feature taper and twist as well as a special low-Reynolds air foil section which varies continually in camber from tip to root. Because of the production method used, the blades are extremely consistent in terms of mass and can be replaced singly should damage occur without losing turbine balance. The alternator and yaw shafts are precision-ground from 316 grade stainless steel, and the D400 Lite alternator body is a robust aluminium alloy casting.

High quality bearings generously sized are used throughout, and these are protected by twin-lipped radial shaft seals. The tail is aluminium sheet formed into a shallow ‘S’ section to impart stiffness and prevent resonance. All aluminium parts are etched and pre-treated before a tough polyester powder coat finish is applied.

The D400 Lite utilises a 12-pole, 3-phase axial field alternator of very high efficiency. It comprises two high flux rare earth magnet rotors with stator coils positioned in between. The stator coils themselves are wound from heavy gauge copper and are encapsulated in a heat-conductive resin. The stator is bolted to a machined shelf within the aluminium housing, ensuring excellent heat dissipation from the windings.

Unlike typical wind generator alternators, D400 Lite’s axial field, ironless design allows the alternator to rotate completely freely without the cogging associated with conventional radial configurations. This promotes early start-up and ensures D400 Lite is exceptionally quiet and vibration free in operation.

A combination of the advanced air blade and alternator design delivers unparalleled efficiency in low wind speeds together with the ability to produce sustained high outputs in high winds.

Eclectic Energy Ltd’s attention to design and quality should ensure your D400 Lite gives years of trouble-free service.

Please feel free to contact us if you require additional advice or guidance.