Overview of Battery Charging and Regulation

A fully charged, 12volt battery will sit at 12.75 volts. A totally flat battery will measure 11.65 volts. 50% discharge (which is as low as it is sensible to routinely discharge a battery) will read 12.25V. If you have access to a hydrometer, you would also be able to measure corresponding differences in the specific gravity of the battery electrolyte between charged and discharged states.

When a battery forms part of an electrical circuit, its terminal voltage defines the voltage of the circuit as a whole. When you are drawing power and no charging device is present, the system voltage will slowly fall in line with the increasing discharge. Note that the best way to observe the rate of drain is to monitor current, i.e. amps DC, as available on a battery monitor such as Link 10. Say the Link reads -4 amps, multiply that by 12.5 (nominal system voltage) and the battery is supplying 50 watts. The monitor should also tell you how long that level of draw can be sustained. If each domestic or ‘service’ battery were 100 amp hours in capacity, two connected in parallel results in a 200 amp hour bank. As mentioned, you should not discharge below 50%, so these two batteries provide 100 amp hours of effective capacity. Assuming a continual 4 amp draw that will provide 25 hours run time to 50% discharge, by which time the battery terminal voltage will have fallen to 12.25.

When a battery forms part of an electrical circuit, its terminal voltage defines the voltage of the circuit as a whole. When you are drawing power and no charging device is present, the system voltage will slowly fall in line with the increasing discharge. Note that the best way to observe the rate of drain is to monitor current, i.e. amps DC, as available on a battery monitor such as Link 10. Say the Link reads -4 amps, multiply that by 12.5 (nominal system voltage) and the battery is supplying 50 watts. The monitor should also tell you how long that level of draw can be sustained. If each domestic or ‘service’ battery were 100 amp hours in capacity, two connected in parallel results in a 200 amp hour bank. As mentioned, you should not discharge below 50%, so these two batteries provide 100 amp hours of effective capacity. Assuming a continual 4 amp draw that will provide 25 hours run time to 50% discharge, by which time the battery terminal voltage will have fallen to 12.25.

Now consider charging sources: the DuoGen (12V) uses an alternator which dependant on how fast the shaft is rotated, will produce from 0 to 60 volts DC when open circuit, i.e. not connected to a load. When the DuoGen is connected to a circuit which includes a battery, the battery defines the circuit voltage. DuoGen’s alternator will spin in a very light breeze, but no current will flow until the alternator is rotating at around 220 RPM. At this point, the alternator will be producing about 12.5 volts. As soon as the alternator voltage exceeds the battery terminal voltage, power (expressed as current) will start to flow around the circuit and be absorbed into the battery, ‘pumped’ by the DuoGen’s alternator.

If we assume there was a strong wind of 25 knots plus, the DG’s alternator might be rotating at 800 RPM. If you measured the alternator output voltage produced open circuit at that RPM, it would be around 40 volts. However, when the DG is connected to the battery, the system voltage is held down by the battery, and you might measure 13.2 volts. The difference between the open-circuit 40 volts and the system 13.2 volts is proportional to the magnitude of the charging current that flows around the circuit. In this case, it would be approximately 20 amps, i.e. 275 watts. Note, if your battery monitor previously read -4 amps DC, it would now read +16.

In short, these elevated voltages just show that a charging current is passing through the batteries, and (within reason) regardless of how much power you apply, i.e. even at 120 amps from the main engine alternator, the system voltage should stay around 1 – 1.5 volts above the battery terminal voltage, assuming the batteries are capable of accepting the charge.

Typical Open Circuit ‘A1 Rest’ Battery terminal voltages

| Charge Level % | Specific Gravity (assumes 18°C ambient temperature) | Voltage |

| 100 | 1250 | 12.75 |

| 90 | 1235 | 12.65 |

| 80 | 1220 | 12.55 |

| 70 | 1205 | 12.45 |

| 60 | 1190 | 12.35 |

| 50 | 1175 | 12.25 |

| 40 | 1160 | 12.1 |

| 30 | 1145 | 11.95 |

| 20 | 1130 | 11.85 |

| 10 | 1115 | 11.75 |

| 0 | 1100 | 11.65 |

Common Lead Acid Battery Problems

| Problem | Probable Causes |

| Battery will not accept charge | Sulphated plates-battery beyond service life |

| Low specific gravity in one cell | Cell sulphated or damaged cell |

| Low specific gravity in all cells | Low charge level or sulphated plates. (associated with repeated undercharging) |

| Battery collapses under load | Low charge level (requires charging) or sulphated plates |

| Battery voltage unusually low –

suspect damaged cell |

Contamination of electrolyte.

Repeated undercharging -mechanical damage to plates Short circuit in cell |

| Battery gets warm when charging | Sulphated plates

Excessive charge current (Due to over voltage i.e. unregulated supply or failed regulator) One or more damaged cells. |

Note, voltage is analogous to pressure and current (amps) equates to volume. The voltage is required to force the charging current around the circuit and through the batteries. The larger the charging current, the quicker you ‘refill’ the battery. Introduce time and you can measure power, i.e. 16 amps for an hour – 16 amp hours restored to the battery. Volts x amps gives watts, i.e. 13.2 x 16 = 212 watts for an hour = 0.212 kW hours back into the battery.

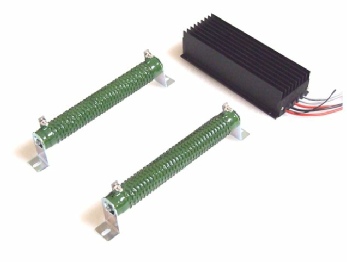

Things start to change as the batteries approach fully charged. The batteries now require more electrical pressure, i.e. voltage to force charging current through the batteries, and the system voltage will begin to rise in response. As the voltage reaches a level indicating ‘fully charged’ the battery regulator will act. The regulator’s function is to protect batteries from damage through overcharging. It does this by accurately measuring battery terminal voltage and as it approaches 14.2 volts, diverting power away from the battery, and dumping the surplus power to a resistive load. This prevents system voltages rising any higher and prevents damage to the battery through internal heating and gassing which occurs when batteries are overcharged.

The dump resistors also provide a load for the turbine to work into once the batteries are full which prevents the air rotor from over speeding. When the charging stops, i.e. when you stop or recover a DuoGen, you will observe that the system voltage will start to fall. This is because the voltage (electrical pressure necessary to drive the charging current) is no longer present. Over time, the battery voltage will settle to an ‘at rest’ level.

The reason that you see often see elevated voltage when charging from the main engine alternator is that it is designed to replace maximum amount of charge in the minimum time. High output, up-rated alternators are often fitted in cruising yachts. These units are often capable of producing as much current as the batteries can absorb. Because the alternators are driven by the ship’s main engine, the availability of power is not an issue. In addition, the ‘smart controller’ typically associated with the engine alternator will apply the highest permissible voltage, in order to drive the maximum charge current through the battery, consistent with the batteries state of charge.

If your yacht was sailing at 10 knots, you would see a similar thing from the deployment of DG in its water mode; there would be lots of power available and the system voltage would rapidly rise to over 13 volts in order to facilitate the high charging currents passing through the battery.

We have already established that overvoltage damages batteries. For this reason it is usual to fit a charge regulator as part of a system. However both DG and D400 will operate perfectly well without a charge regulator. Omitting regulators from the renewables may be feasible on live-aboard vessels with very large capacity battery banks, i.e. 800 amp hour plus. One advantage is any possibility of unwanted interaction between the wind turbine and the solar regulators is avoided. Such interaction can lead to premature ‘dumping’ and a loss of power. However this strategy also means that battery state must be monitored on a regular basis with charging stopped or started manually as required.

We have already established that overvoltage damages batteries. For this reason it is usual to fit a charge regulator as part of a system. However both DG and D400 will operate perfectly well without a charge regulator. Omitting regulators from the renewables may be feasible on live-aboard vessels with very large capacity battery banks, i.e. 800 amp hour plus. One advantage is any possibility of unwanted interaction between the wind turbine and the solar regulators is avoided. Such interaction can lead to premature ‘dumping’ and a loss of power. However this strategy also means that battery state must be monitored on a regular basis with charging stopped or started manually as required.

It is generally recommended that a regulator is installed with DG or D400. If interaction is an issue one or both regulators can be fitted with a bypass switch (refer to last page of regulator instructions). Once the regulator bypassed, it becomes vital to monitor the battery state and manually stop the DG or D400 when system voltages approach 14.2.

Refer to the table above which is a useful guide to battery state.